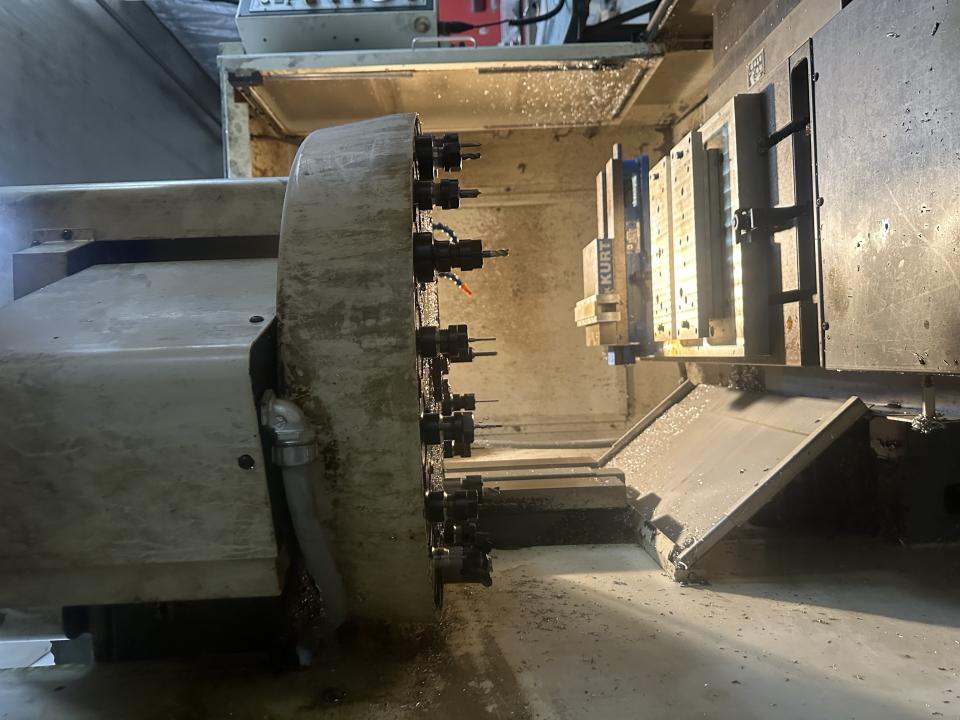

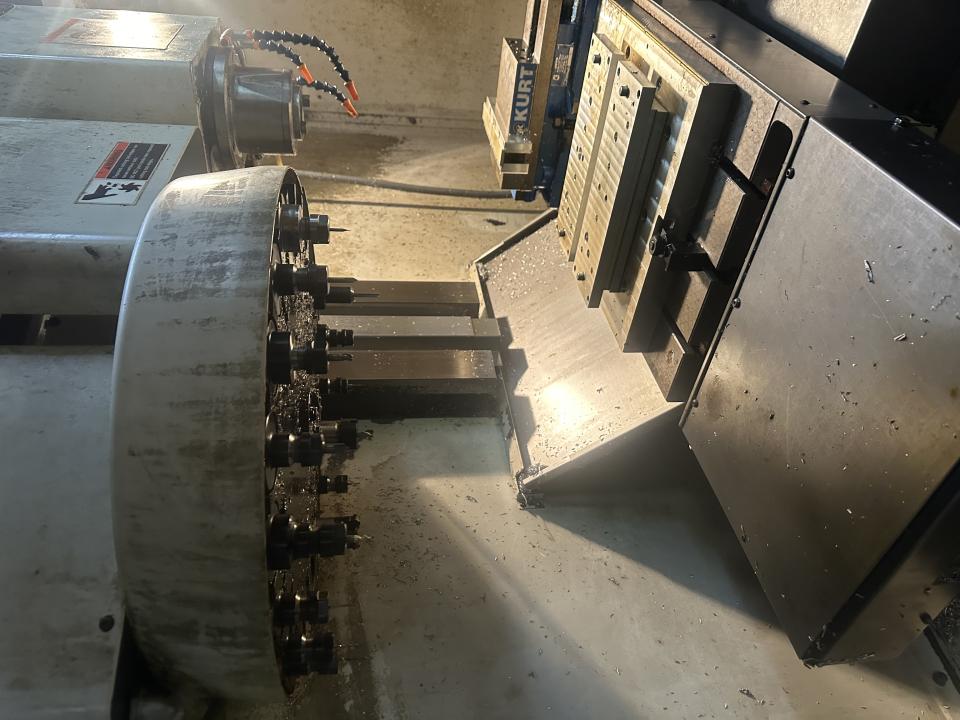

Well maintained and carefully operated, complete system 1997 FADAL 3016 3-axis CNC milling machine with tool holders, consumables, and design software.

Zero time on complete rebuild.

X-axis travel 30”

Y-axis travel 16”

Z-axis travel 20”

Rapid feed X-axis, Y-axis 900" per minute Z-axis 700" per minute

Feed .01-400" per minute

Table load capacity approximately 2,730 pounds

Weight approximately 8,300 pounds.

15 hp Baldor motor.

Rebuilt 10,000 rpm water cooled spindle.

New ball screws.

New caged bearings throughout.

New belts and cables.

New lubricating tubes throughout.

Complete tune up by factory trained personnel.

Accuracy tested repeatability tolerance within 7 millionths. Test results available.

Machine has all available factory options:

Rigid tapping,

Remote height setter

Also includes:

38 10,000-rpm rated tool holders, collets of different diameter, etc.

Thousands of dollars assorted end mills, face mills, spot drills, drill bits, etc

Roll around tool cabinet

Work Table with tool holder change fixture mounted

Computer with Windows operating systems with several thousand dollars software installed

Mastercam CAD CAM design software package, Cimco tool path editor

100’ sending cable from computer to machine

2 Kurt machinists vices, numerous vice jaws, parallel bar sets, 1-2-3blocks, lots of clamps for various fixture position mounting requirements,

Precision measuring equipment, magnetic mounting tools, everything necessary to machine a precision part.

New 5 gallon bucket way lune oil

New 5 gallon bucket coolant concentrate 40:1 ratio

Note: This is a complete system, extremely accurate, limited only by your imagination; for 3-D designing and machining all types of metals, plastics, wood, etc. with with predictable reliability.

Ready to work

Contact me +1 208 670 2871